A stack of previous cellphones are seen earlier than recycling course of in Kocaeli, Turkiye on October 14, 2024.

Anadolu | Anadolu | Getty Photographs

Because the U.S. and China vie for financial, technological and geopolitical supremacy, the crucial parts and metals embedded in expertise from shopper to industrial and navy markets have turn out to be a pawn within the wider battle. That is nowhere extra so the case than in China’s leverage over the uncommon earth metals provide chain. This previous week, the Division of Protection took a big fairness stake in MP Supplies, the corporate working the one uncommon earths mining operation within the U.S.

However there’s one other choice to fight the uncommon earths scarcity that goes again to an older thought: recycling. The enterprise has come a good distance from accumulating cans, bottles, plastic, newspaper and different shopper disposables, in any other case destined for landfills, to recreate all kinds of recent merchandise.

At the moment, next-generation recyclers — a mixture of legacy firms and startups — are innovating methods to assemble and course of the ever-growing mountains of digital waste, or e-waste, which contains end-of-life and discarded computer systems, smartphones, servers, TVs, home equipment, medical units, and different electronics and IT tools. And they’re doing so in a approach that’s aligned to the latest crucial applied sciences in society. Most not too long ago, spent EV batteries, wind generators and photo voltaic panels are fostering a burgeoning recycling area of interest.

The e-waste recycling alternative is not restricted to uncommon earth parts. Any electronics that may’t be wholly refurbished and resold, or cannibalized for alternative components wanted to maintain current electronics up and working, can berecycled to strip out gold, silver, copper, nickel, metal, aluminum, lithium, cobalt and different metals important to producers in numerous industries. However more and more, recyclers are extracting rare-earth parts, corresponding to neodymium, praseodymium, terbium and dysprosium, that are crucial in making every little thing from fighter jets to energy instruments.

“Recycling [of e-waste] hasn’t been taken too significantly till not too long ago” as a significant supply of provide, stated Kunal Sinha, world head of recycling at Swiss-based Glencore, a significant miner, producer and marketer of metals and minerals — and, to a a lot lesser however rising diploma, an e-waste recycler. “Lots of people are nonetheless sleeping on the wheel and do not understand how huge this may be,” Sinha stated.

Historically, U.S. producers buy important metals and uncommon earths from home and international producers — an inordinate quantity based mostly in China — that fabricate mined uncooked supplies, or by commodities merchants. However with these provide chains now disrupted by unpredictable tariffs, commerce insurance policies and geopolitics, the marketplace for recycled e-waste is gaining significance as a strategy to feed the insatiable electrification of every little thing.

“America imports lots of electronics, and all of that’s coming with gold and aluminum and metal,” stated John Mitchell, president and CEO of the International Electronics Affiliation, an trade commerce group. “So there’s an incredible alternative to truly have the tariffs be an impetus for better recycling on this nation for items that we do not have, however are shopping for from different nations.”

With copper, different metals, ‘recycling goes to play enormous function’

Though recycling contributes solely round $200 million to Glencore’s whole EBITDA of almost $14 billion, the strategic consideration and time the enterprise will get from management “is way more than that share,” Sinha stated. “We imagine that lots of mining is important to get to all of the copper, gold and different metals which can be wanted, however we additionally acknowledge that recycling goes to play an enormous function,” he stated.

Glencore has operated an enormous copper smelter in Quebec, Canada, for nearly 20 years on a website that is almost 100-years-old. The ability processes principally mined copper concentrates, although 15% of its feedstock is recyclable supplies, corresponding to e-waste that Glencore’s world community of 100-plus suppliers accumulate and type. The smelter pioneered the method for recovering copper and valuable metals from e-waste within the mid Nineteen Eighties, making it one of many first and largest of its sort on this planet. The smelted copper is refined into contemporary slabs which can be bought to producers and merchants. The identical facility additionally produces refined gold, silver, platinum and palladium recovered from recycling feeds.

The significance of copper to OEMs’ provide chains was magnified in early July, when costs hit an all-time excessive after President Trump stated he would impose a 50% tariff on imports of the metallic. The U.S. imports slightly below half of its copper, and the tariff hike — like different new Trump commerce insurance policies — is meant to spice up home manufacturing.

Worth of copper year-to-date 2025.

It takes round three a long time for a brand new mine within the U.S. to maneuver from discovery to manufacturing, which makes recycled copper look all of the extra engaging, particularly as demand retains rising. In line with estimates by energy-data agency Wooden Mackenzie, 45% of demand might be met with recycled copper by 2050, up from a few third immediately.

Overseas recycling firms have begun investing within the U.S.-based services. In 2022, Germany’s Wieland broke floor on a $100-million copper and copper alloy recycling plant in Shelbyville, Kentucky. Final yr, one other German agency, Aurubis, began building on an $800-million multi-metal recycling facility in Augusta, Georgia.

“As the primary main secondary smelter of its type within the U.S., Aurubis Richmond will permit us to maintain strategically vital metals within the financial system, making U.S. provide chains extra impartial,” stated Aurubis CEO Toralf Haag.

Large quantities of e-waste

The proliferation of e-waste could be traced again to the Nineties, when the web gave delivery to the digital financial system, spawning exponential progress in electronically enabled merchandise. The development has been supercharged by the emergence of renewable power, e-mobility, synthetic intelligence and the build-out of knowledge facilities. That interprets to a continuing turnover of units and tools, and large quantities of e-waste.

In 2022, a document 62 million metric tons of e-waste have been produced globally, up 82% from 2010, in accordance with the most up-to-date estimates from the United Nations’ Worldwide Telecommunications Union and analysis arm UNITAR. That quantity is projected to achieve 82 million metric tons by 2030.

The U.S., the report stated, produced simply shy of 8 million tons of e-waste in 2022. But solely about 15-20% of it’s correctly recycled, a determine that illustrates the untapped marketplace for e-waste retrievables. The e-waste recycling trade generated $28.1 billion in income in 2024, in accordance with IBISWorld, with a projected compound annual progress price of 8%.

Whether or not it is refurbished and resold or recycled for metals and rare-earths, e-waste that shops information — particularly smartphones, computer systems, servers and a few medical units — should be wiped of delicate data to adjust to cybersecurity and environmental laws. The service, known as IT asset disposition (ITAD), is obtainable by typical waste and recycling firms, together with Waste Administration, Republic Companies and Clear Harbors, in addition to specialists corresponding to Sims Lifecycle Companies, Digital Recyclers Worldwide, All Inexperienced Electronics Recycling and Full Circle Electronics.

“We’re undoubtedly seeing a little bit of an inflow of [e-waste] coming into our warehouses,” stated Full Circle Electronics CEO Dave Every day, including, “I feel that is because of some early refresh cycles.”

That is a reference to companies and customers selecting to get forward of the customary three-year time-frame for buying new electronics, and discarding previous stuff, in anticipation of tariff-related value will increase.

Every day is also witnessing elevated demand amongst downstream recyclers for e-waste Full Circle Electronics cannot refurbish and promote at wholesale. The corporate dismantles and separates it into 40 or 50 several types of materials, from keyboards and mice to circuit boards, wires and cables. Recyclers harvest these gadgets for metals and uncommon earths, which proceed to go up in value on commodities markets, earlier than reentering the provision chain as core uncooked supplies.

Even earlier than the Trump administration’s efforts to revitalize American manufacturing by remodeling commerce offers, and up to date modifications in tax credit key to the trade in Trump’s tax and spending invoice, entrepreneurs have been launching e-waste recycling startups and growing applied sciences to course of them for home OEMs.

“Many areas of the world have been form of lazy about processing e-waste, so lots of it goes offshore,” Sinha stated. In response to that imbalance, “There appears to be a development of nationalizing e-waste, as a result of folks instantly notice that we now have the identical metals [they’ve] been searching for” from abroad sources, he stated. “Folks have been rethinking the worldwide provide chain, that they are too lengthy and must be extra localized.”

China instructions 90% of uncommon earth market

A number of startups are inclined to deal with a specific sort of e-waste. Currently, uncommon earths have garnered great consideration, not simply because they’re in excessive demand by U.S. electronics producers but additionally to minimize dependence on China, which dominates mining, processing and refining of the supplies. Within the manufacturing of rare-earth magnets — utilized in EVs, drones, shopper electronics, medical units, wind generators, navy weapons and different merchandise — China instructions roughly 90% of the worldwide provide chain.

The lingering U.S.–China commerce battle has solely exacerbated the disparity. In April, China restricted exports of seven uncommon earths and associated magnets in retaliation for U.S. tariffs, a transfer that compelled Ford to close down factories due to magnet shortages. China, in mid-June, issued short-term six-month licenses to sure main U.S. automaker suppliers and choose companies. Exports are flowing once more, however with delays and nonetheless nicely beneath peak ranges.

The U.S. is making an attempt to catch up. Earlier than this previous week’s Trump administration deal, the Biden administration awarded $45 million in funding to MP Supplies and the nation’s lone uncommon earths mine, in Mountain Go, California. Again in April, the Inside Division authorised improvement actions on the Colosseum uncommon earths undertaking, situated inside California’s Mojave Nationwide Protect. The undertaking, owned by Australia’s Dateline Sources, will doubtlessly turn out to be America’s second uncommon earth mine after Mountain Go.

A wheel loader takes ore to a crusher on the MP Supplies uncommon earth mine in Mountain Go, California, U.S. January 30, 2020. Image taken January 30, 2020.

Steve Marcus | Reuters

In the meantime, a number of recycling startups are extracting uncommon earths from e-waste. Illumynt has a sophisticated course of for recovering them from decommissioned laborious drives procured from information facilities. In April, laborious drive producer Western Digital introduced a collaboration with Microsoft, Important Supplies Recycling and PedalPoint Recycling to tug uncommon earths, in addition to copper, gold, aluminum and metal, from end-of-life drives.

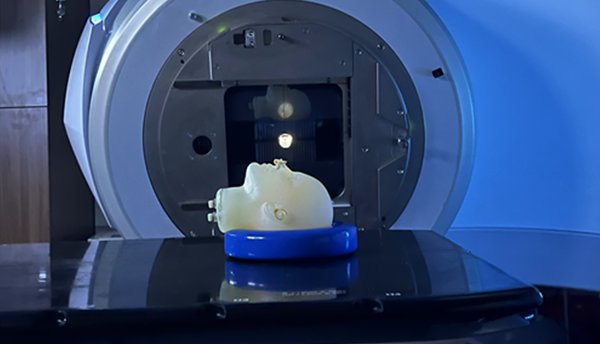

Canadian-based Cyclic Supplies invented a course of that recovers rare-earths and different metals from EV motors, wind generators, MRI machines and data-center e-scrap. The corporate is investing greater than $20 million to construct its first U.S.-based facility in Mesa, Arizona. Late final yr, Glencore signed a multiyear settlement with Cyclic to supply recycled copper for its smelting and refining operations.

One other scorching feedstock for e-waste recyclers is end-of-life lithium-ion batteries, a supply of not solely lithium but additionally copper, cobalt, nickel, manganese and aluminum. These supplies are important for manufacturing new EV batteries, which the Large Three automakers are closely invested in. Their initiatives, nevertheless, are threatened by potential reductions within the Biden-era 45X manufacturing tax credit score, featured within the new federal spending invoice.

It is too quickly to know the way which may affect battery recyclers — together with Ascend Parts, American Battery Know-how, Cirba Options and Redwood Supplies — who themselves qualify for the 45X and different tax credit. They could truly be aided by different provisions within the funds invoice that profit a home provide chain of crucial minerals as a strategy to undercut China’s dominance of the worldwide market.

Nonetheless, that looming uncertainty must be a warning signal for e-waste recyclers, stated Sinha. “Watch out to not construct a recycling firm on the again of 1 tax credit score,” he stated, “as a result of it may be short-lived.”

Investing in recyclers could be precarious, too, Sinha stated. Whereas he is completely happy to see recycling getting its due as a significant supply of provide, he cautions folks to watch out when investing on this house. Startups could have developed new applied sciences, however lack adequate enterprise fundamentals. “Do not make investments on the hype,” he stated, “however on the basics.”

Glencore, paradoxically sufficient, is a working example. It has invested $327.5 million in convertible notes in battery recycler Li-Cycle to supply feedstock for its smelter. The Toronto-based startup had damaged floor on a brand new facility in Rochester, New York, however bumped into monetary difficulties and filed for Chapter 15 chapter safety in Could, prompting Glencore to submit a “stalking horse” credit score bid of at the very least $40 million for the stalled undertaking and different belongings.

Even so, “the present atmosphere will result in extra startups and investments” in e-waste recycling, Sinha stated. “We’re investing ourselves.”