A brand new, simply adopted, 3D-printed system will allow scientists to create fashions of human tissue with even larger management and complexity. An interdisciplinary group of researchers on the College of Washington and UW Drugs led the event of the system.

3D tissue engineering, which lately has undergone different main advances in pace and accuracy, helps biomedical researchers design and check therapies for a variety of ailments.

One purpose of tissue engineering is to create lab-made environments that recreate the pure habitats of cells.

Suspending cells in a gel between two freestanding posts is without doubt one of the present modeling platforms for rising coronary heart, lung, pores and skin and musculoskeletal tissues.

Whereas this strategy permits cells to behave as they’d contained in the physique, it has not made it straightforward to review a number of tissue sorts collectively. Extra exact management over the composition and spatial association of tissues would permit scientists to mannequin advanced ailments, equivalent to neuromuscular problems.

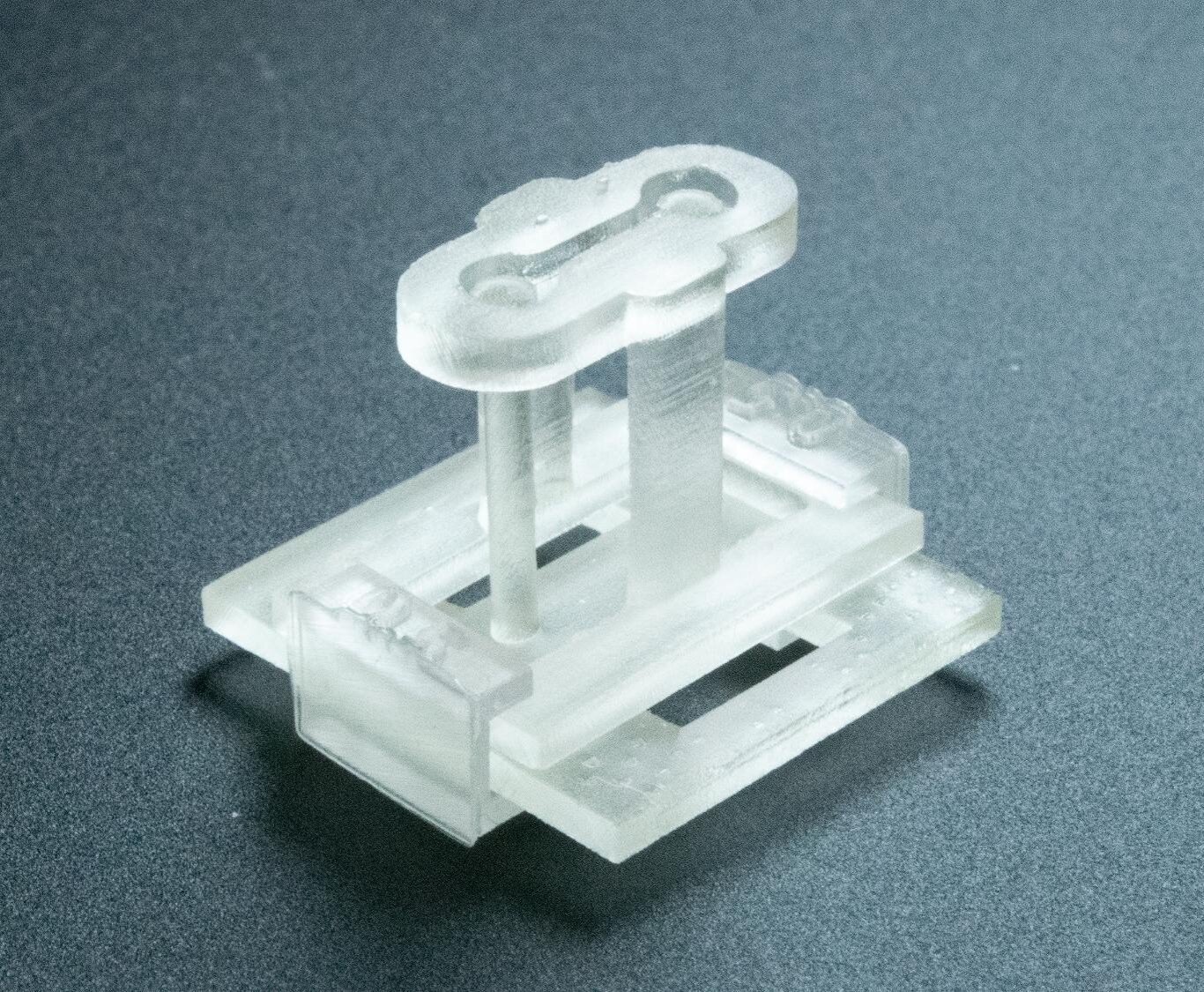

A paper printed in Superior Science particulars how the brand new platform lets scientists look at how cells reply to mechanical and bodily cues, whereas creating distinct areas in a suspended tissue. The 3D-printed system is called STOMP (Suspended Tissue Open Microfluidic Patterning).

Ashleigh Theberge, UW professor of chemistry, and Nate Sniadecki, professor of mechanical engineering and interim codirector of the UW Drugs Institute for Stem Cell and Regenerative Drugs, led the scientific crew. The group confirmed that their system can recreate organic interfaces like bone and ligament, or fibrotic and wholesome coronary heart tissue.

The primary authors of the paper have been Amanda Haack, a scholar within the Faculty of Drugs’s medical scientist program and postdoctoral fellow within the Theberge Lab, and Lauren Brown, a Ph.D. scholar in chemistry. UW college members Cole DeForest, professor of chemical engineering and bioengineering, and Tracy Popowics, professor of oral biology within the Faculty of Dentistry, are co-authors.

STOMP enhances a tissue-engineering methodology known as casting, which the researchers in contrast in easy phrases to creating Jell-O in a dessert mould. Within the lab, the gel is a mix of residing and artificial supplies. These are pipetted right into a body relatively than poured right into a mould. STOMP makes use of capillary motion—consider water flowing up a straw in a consuming glass—to allow scientists to house out completely different cell sorts in no matter sample an experiment requires, like a cook dinner evenly spreading items of fruit in Jell-O.

The researchers put STOMP to the check in two experiments: one which in contrast the contractile dynamics of diseased and wholesome engineered coronary heart tissue, and one other that fashions the ligament that connects a tooth to its bone socket.

The STOMP system is in regards to the measurement of a fingertip. It docks on to a two-post system initially developed by the Sniadecki Lab to measure the contractile pressure of coronary heart cells. The tiny piece of {hardware} comprises an open microfluidic channel with geometric options to control the spacing and composition of various cell sorts, and for creating a number of areas inside single suspended tissue with out the necessity for added gear or capabilities.

Hydrogel know-how from the DeForest Analysis Group souped up STOMP with one other design characteristic: degradable partitions. Tissue engineers can break down the edges of the system and depart the tissues intact.

“Usually once you put cells in a 3D gel,” Sniadecki mentioned, “they are going to use their very own contractile forces to drag all the things collectively—which causes the tissue to shrink away from the partitions of the mould. However not each cell is tremendous robust, and never each biomaterial can get transformed like that. In order that type of nonstick high quality gave us extra versatility.”

Theberge is happy about how different groups will use STOMP.

“This methodology opens new potentialities for tissue engineering and cell signaling analysis,” she mentioned. “It was a real crew effort of a number of teams working throughout disciplines.”

Extra info:

Amanda J. Haack et al, Suspended Tissue Open Microfluidic Patterning (STOMP), Superior Science (2025). DOI: 10.1002/advs.202501148

Quotation:

3D-printed system allows exact modeling of advanced human tissues within the lab (2025, Might 24)

retrieved 24 Might 2025

from https://medicalxpress.com/information/2025-05-3d-device-enables-precise-complex.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.