This text was produced by ProPublica in partnership with The Oregonian/OregonLive. Join Dispatches, to get tales like this one as quickly as they’re revealed.

In Phnom Penh’s scorching season, when the Cambodian capital’s sweltering, subtropical air routinely soars to 100 levels, extra staff than typical visited the infirmaries inside a manufacturing facility that made child garments for Nike, the world’s largest athletic attire model.

As many as 15 individuals a month sometimes turned too weak to work in Could and June, in accordance with a medical employee employed by the manufacturing facility. Even at different instances of yr, she mentioned, eight to 10 staff wound up within the clinic month-to-month as a result of they felt weak, together with one or two a month who fell unconscious and wanted to go to the hospital.

Different former staff advised ProPublica they often noticed two or three individuals a day taken to an on-site clinic. One described how he carried staff too weak to stroll. One other mentioned she noticed skinny staff being taken to the clinic, their faces pale and eyes closed.

Y&W Garment’s staff — at one time numbering round 4,500 — operated stitching machines and packaged clothes in cavernous buildings with followers however no air-con. The followers generally broke and weren’t mounted, one employee mentioned. One other mentioned the within of the manufacturing facility might get hotter than it was open air. “It’s so scorching,” mentioned Phan Oem, 53, who began working there shortly after the manufacturing facility opened in 2012. “I’m sweaty. It’s too scorching.”

Credit score:

Sarahbeth Maney/ProPublica

Staff have fainted for years inside Cambodia’s garment factories, the place greater than 57,000 individuals now produce Nike items. Folks at Nike’s suppliers fainted en masse in 2012, 2014, 2017, 2018 and 2019, in accordance with information reviews on the time, a part of a string of occasions wherein hundreds of Cambodians acquired sick, vomited or collapsed on the job. (The time period “fainting” in Cambodia is used for situations that vary from dropping consciousness to turning into too dizzy or weak to work.)

Nike had moved into Cambodia in 2000, simply two years after co-founder Phil Knight promised to finish labor abuses that accompanied its push into Southeast Asia.

Nike took motion after faintings made headlines. It despatched executives on a fact-finding mission in 2012. It requested for worldwide labor officers to research. Nike in 2017 advised The Guardian, “We take the problem of fainting significantly, as it may be each a social response and a sign of points inside a manufacturing facility that will require corrective motion.”

But for all of the measures Nike says it depends on to maintain staff secure, which embrace warmth requirements in factories, inner and exterior audits, introduced and unannounced visits, Y&W staff mentioned fainting continued throughout the two years Nike merchandise had been made there.

Jill Tucker, who led the U.N.-backed oversight group Higher Factories Cambodia from 2011 to 2014, mentioned she was not shocked to listen to that staff recurrently fainted at Y&W Garment.

The issue is “a consequence of low wages and poor working situations that proceed, even after many years of labor on this situation,” Tucker mentioned. “Folks work very arduous for little or no pay.”

Representatives of Y&W Garment and its father or mother firm, Hong Kong-based Wing Luen Knitting Manufacturing unit Ltd., didn’t reply to emails, textual content messages or calls.

It’s unclear what Nike knew about working situations on the Phnom Penh manufacturing facility. Higher Factories Cambodia, whose audits Nike has mentioned up to now it relied on to observe suppliers, advised ProPublica it didn’t know staff had been fainting at Y&W. ProPublica beforehand reported on low wages at Y&W, the place simply 1% of staff made what Nike says is typical of staff in its provide chain.

Nike didn’t reply ProPublica’s questions, together with about whether or not it stopped working with the Y&W manufacturing facility due to any violations of its code of conduct. Y&W Garment stopped making Nike attire in late 2023, shortly earlier than going bankrupt, staff advised ProPublica. Nike mentioned in a press release that it’s “dedicated to moral and accountable manufacturing” and units clear expectations for its suppliers by means of its code of conduct.

Staff mentioned Nike clothes at Y&W had been produced beneath the auspices of Haddad Manufacturers, a non-public New York firm whose web site says it produces Nike youngsters’s clothes and enforces Nike’s code of conduct. Haddad didn’t reply to repeated emails; somebody who answered its telephone hung up on a reporter who known as, and nobody responded to a subsequent voicemail.

On its web site, Haddad says it really works straight with its factories “to make sure that every of our suppliers has the flexibility to not solely manufacture our product, however to take action responsibly — for the employees, for the setting, and for our clients.”

At Y&W Garment, a set of corrugated metallic buildings alongside either side of a busy highway in quickly developed southern Phnom Penh, two staff mentioned faintings had been so frequent that they had been now not stunning. The medical worker interviewed by ProPublica blamed extra time hours and staff not sleeping a lot or consuming sufficient.

If staff fell unconscious, they went to the hospital, the medical employee mentioned. In any other case, they got calcium tablets and allowed to relaxation on a skinny mat unfold on a metallic cot.

Then, she mentioned, they sometimes went again to work.

Y&W will not be an remoted case. The Cambodian authorities reported greater than 4,500 faintings in factories between 2017 and 2019, in accordance with information reviews, an issue it has attributed to pesticide spraying, chemical substances utilized in manufacturing, warmth, poor vitamin and insufficient air flow. Media reviews additionally quoted the federal government citing psychological components, similar to staff’ beliefs in supernatural forces.

Invoice Clinton got down to alleviate harsh working situations in Cambodia’s factories in 1999, when as president he signed a commerce deal that drastically expanded Cambodian garment exports to america.

Cambodia’s rising business on the time was serving to to shore up the nation’s economic system because it recovered from warfare and the Seventies Khmer Rouge genocide. A couple of months after the commerce deal was signed, an incident illustrated why labor points had been a priority. Greater than two dozen exhausted staff fainted at a Phnom Penh garment manufacturing facility. A union consultant advised a neighborhood newspaper they’d been working 14-hour days, fearful they’d be fired.

The Clinton commerce settlement known as for making a labor monitor to deliver Cambodia’s factories as much as worldwide requirements. If the producers improved their working situations, america would develop its import quotas. Higher Factories Cambodia, which is a part of the United Nations’ Worldwide Labor Group and has been funded by the U.S. Labor Division, started working in 2001.

Credit score:

AFP by way of Getty Photos

The group would guarantee “American corporations like Hole or Nike really feel secure putting orders in Cambodia, realizing that factories adjust to human rights, labor legal guidelines and good working situations,” Van Sou Ieng, then-president of the Cambodian garment business’s commerce affiliation, advised Vogue in 2002.

Nike, which had withdrawn from the nation when a BBC investigation in 2000 discovered youngsters as younger as 12 working for a Nike provider, returned after Higher Factories Cambodia launched. The corporate has repeatedly pointed to Higher Factories Cambodia as a vital a part of its manufacturing facility oversight through the years. In 2012, Nike mentioned that it relied on the group’s manufacturing facility audits, somewhat than conducting its personal, to make sure enough working situations within the nation. (Nike didn’t reply when requested about Higher Factories Cambodia’s present function in auditing.)

In contrast to office security regulators in america, Higher Factories Cambodia was not given enforcement energy to fantastic or shut down drawback factories. As well as, business and authorities made up two-thirds of the group’s advisory committee. That gave them rather more affect than staff, in accordance with Tucker.

In 2012, Higher Factories Cambodia took on mass faintings with one thing known as the One Change Marketing campaign. It adopted a string of media reviews that prompted a frantic seek for options, Tucker mentioned. The thought was to get every manufacturing facility proprietor to do one factor to scale back fainting that the regulation didn’t already require. It is perhaps free lunches, snacks or twice-daily paid train applications to fight fatigue and monotony — aerobics for staff who had been prone to being malnourished.

“It was simply lame,” mentioned Tucker, who was the group’s chief on the time. She mentioned she got here to appreciate that the company was taking the improper strategy, specializing in short-term initiatives as a substitute of tackling the foundation causes of issues.

Higher Factories Cambodia has had a combined report since then.

It has known as consideration to the failure of Cambodian factories to obey labor requirements. The group in February reported that nearly half of the greater than 350 factories it inspected in 2023 made staff work extreme extra time hours, whereas two-thirds of factories had been hotter than the group’s really helpful 90 levels Fahrenheit. The report didn’t determine the factories.

Daramongkol Keo, a Higher Factories Cambodia spokesperson, mentioned the group has seen significant enhancements in wage compliance, gender equality, working hours and office security whereas it has been working. He mentioned the group has constantly monitored and reported fainting incidents in Cambodia.

For all the problems it’s uncovered, although, labor advocates say its inspectors miss many extra.

A 2024 report from the Middle for Alliance of Labor and Human Rights, a Cambodian authorized support group, discovered that Higher Factories gave excellent marks for labor union compliance even at factories the place staff mentioned union busting was pervasive.

If Higher Factories’ findings don’t mirror precise working situations, the report mentioned, “then everyone seems to be taking part — whether or not willingly or not — in a large-scale whitewashing scheme.”

When requested for a response to the criticism, the chief of Higher Factories Cambodia, Froukje Boele, advised ProPublica, “we admire the report’s focus and emphasis on working situations, freedom of affiliation and collective bargaining.”

Cambodia’s garment business praises Higher Factories Cambodia’s work. Ken Bathroom, the present head of the business’s commerce group, mentioned this system enhances authorities and business efforts “to make sure excessive ranges of social and labor compliance.”

Higher Factories Cambodia was unaware of the incidents at Y&W Garment that former staff described to ProPublica, in accordance with Keo, the spokesperson. That’s regardless of conducting 4 inspections from March 2020 by means of July 2023.

The group acknowledged some shortcomings of its two-day, unannounced audits in a report this yr. It mentioned issues like sexual harassment and efforts to intervene with union organizing are arduous to confirm.

“If fainting incidents had been identified however not adequately addressed on the manufacturing facility stage,” Keo advised ProPublica, “it underscores the broader challenges of enforcement and accountability throughout the business.”

Had the problem of faintings been confined to Cambodia, the shortcomings of Higher Factories Cambodia would possibly clarify Nike’s failure to rid its provide chain of the issue. That wasn’t the case, in accordance with findings of a labor monitoring group in Vietnam in 2016.

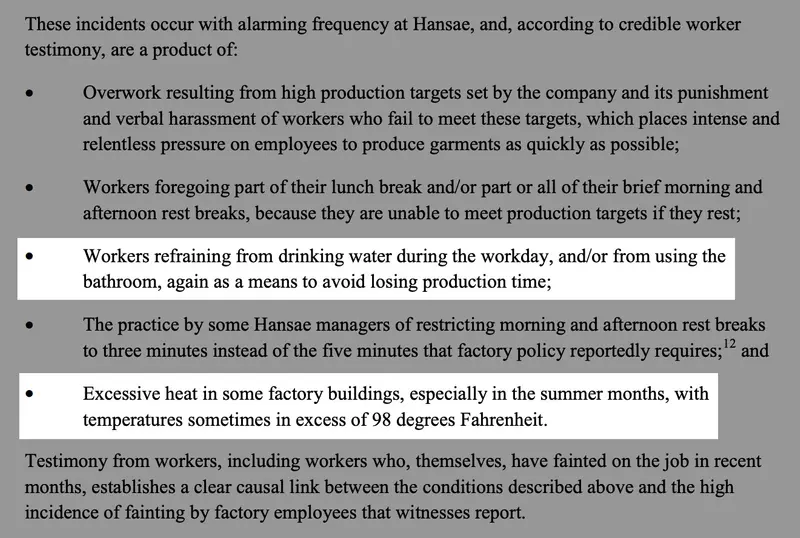

That yr, the Employee Rights Consortium described quite a few faintings at a Vietnamese provider of Nike and different Western manufacturers. Staff at Hansae Vietnam in Ho Chi Minh Metropolis advised the group that stress to fulfill manufacturing targets within the un-air-conditioned manufacturing facility was so excessive that they didn’t drink water to save lots of time visiting the bathroom. Tons of of staff went on strike, twice.

Credit score:

Obtained and highlighted by ProPublica

The consortium known as in a licensed industrial hygienist, Garrett Brown, to conduct an impartial investigation.

It was months earlier than Brown was allowed to enter the 12-building manufacturing facility complicated that employed roughly 10,000 individuals. Inside, he and one other colleague recorded temperatures as excessive as 95 levels, he mentioned.

“It was goddamn scorching inside these crops, for certain,” Brown advised ProPublica. By the tip of the day, he mentioned, he was exhausted.

“You’re sweating profusely, strolling between the buildings and within the buildings as properly,” he mentioned. “And we had been simply doing it for eight hours — and loads of staff had been going for 10, 12, 14 hours.”

Hansae, which didn’t reply to emails from ProPublica, developed a remediation plan to repair the issues Brown and others had recognized. It included putting in cooling methods and shutting off the electrical energy in manufacturing areas to make sure that staff took lunch breaks. Nike now not produces on the manufacturing facility.

Temperatures got here down far quicker in 2021 when Nike was confronted with an worker grievance about dizziness and dehydration at Nike’s retail retailer in downtown Portland, which sits not removed from the corporate’s suburban company headquarters.

In contrast to in Vietnam, the grievance was about temperatures within the low 80s — “tremendous scorching,” one employee advised an inspector from the Oregon Occupational Security and Well being Division — not the mid-90s that Brown measured in Ho Chi Minh Metropolis. And in contrast to in Vietnam, it took days, not months, for office security inspectors to get inside.

In keeping with a state report, the inspectors shortly found that the issue was already being addressed, at the very least quickly. Nike had introduced in 5 transportable air conditioners, spending what an organization official would later estimate was $40,000 to get the summer time warmth beneath management.

Keat Soriththeavy and Ouch Sony contributed reporting and translation. Kirsten Berg of ProPublica and Matthew Kish of The Oregonian/OregonLive contributed analysis.