The query was a easy one: Had Nike, the athletic attire model dogged by sweatshop allegations greater than 20 years in the past, really develop into a beacon of environmental stewardship and honest labor practices, because it claimed?

As editor for ProPublica’s Northwest crew and a longtime Oregonian, I used to be as wanting to know the reply because the Portland-based reporter who posed the query, Rob Davis.

Nike is woven into Oregon’s material. It’s one of many Portland space’s largest employers and one of many state’s few Fortune 500 firms. Nike’s headquarters within the Portland suburbs is a 400-acre complicated of buildings, operating paths and sports activities fields the place style design and athleticism meet. On the College of Oregon, alma mater of Nike co-founder Phil Knight, buildings throughout the campus bear his title or the names of his family.

The difficulty was that the reply to Davis’ query primarily lay throughout the Pacific Ocean. Though ProPublica is undaunted by tales that take time and, sure, cash — see current reporting by reporters Josh Kaplan and Brett Murphy from Gambia, for instance — Davis first wanted to show to editors that an abroad journey would convey us a narrative that broke new floor.

One among our most necessary choices early on was to associate with reporter Matthew Kish and his editors at The Oregonian/OregonLive, the place Davis and I labored beforehand. Kish has coated Nike for greater than a decade and is aware of the corporate in addition to maybe any reporter within the nation.

Kish and Davis began reviewing public studies that Nike had put out over the previous 20 years and each information article they may discover concerning the firm’s efforts within the realm of social accountability. Davis spoke by cellphone with labor advocates across the globe. He even discovered a couple of manufacturing facility employees in Asia prepared to speak in late-night (for them) video calls about their working situations.

The nut that Davis and Kish couldn’t crack was Nike itself. The reporters advised Nike’s public relations crew about their curiosity. May Nike staffers share what they have been discovering in manufacturing facility audits or how they have been guaranteeing compliance with Nike’s code of conduct? The PR folks at varied factors supplied some background info, together with excerpts of previous company studies, however the firm selected to not make anybody obtainable for on-the-record interviews at that stage.

(I additionally requested Nike final week to weigh in on the corporate’s interactions with Kish and Davis or concerning the tales they’ve written for this sequence; a Nike spokesperson declined to remark to me on the document.)

With layoffs hitting Nike final 12 months, Kish and Davis had a gap to speak with insiders about one explicit facet of the corporate’s social accountability efforts. Pursuing a tip, the 2 labored with analysis reporter Alex Mierjeski to compile an inventory of staff who had labored in sustainability roles. The reporters began knocking on digital doorways: about 100 of them. They established that Nike’s reorganization had taken a heavy toll on the workforce whose efforts included decreasing the corporate’s carbon footprint.

This time, Nike responded by granting an interview with its chief sustainability officer, the one interview the corporate has given for this undertaking up to now throughout greater than a 12 months of reporting. It lasted 17 minutes. She mentioned the corporate remained dedicated to sustainability and described its technique as “embedding” the work all through the corporate.

We printed tales laying out the departures and one different improvement that appeared to go towards Nike’s declared intent to assist the planet: growing emissions from its personal jets.

But one thing remained lacking from our reporting. The previous sustainability employees spoke English. Many have been primarily based in Oregon. That they had on-line presences. Understanding working situations in Nike’s factories referred to as for gaining a better vantage level on the corporate’s far-flung overseas provide chain.

Davis zeroed in on one particular declare from Nike. The corporate has mentioned that the factories for which it has knowledge pay their employees, on common, 1.9 occasions the native minimal wage. It supplied no breakdown of factories included within the calculation, and it wasn’t clear how broadly pay would possibly fluctuate from the common. So Davis began requesting paystubs for employees throughout the globe. We hoped that even scattered knowledge would assist us check Nike’s math.

Paystubs trickled in. A handful of employees from a manufacturing facility in Central America. Extra from Indonesia. A smattering from Cambodia.

Then, a breakthrough.

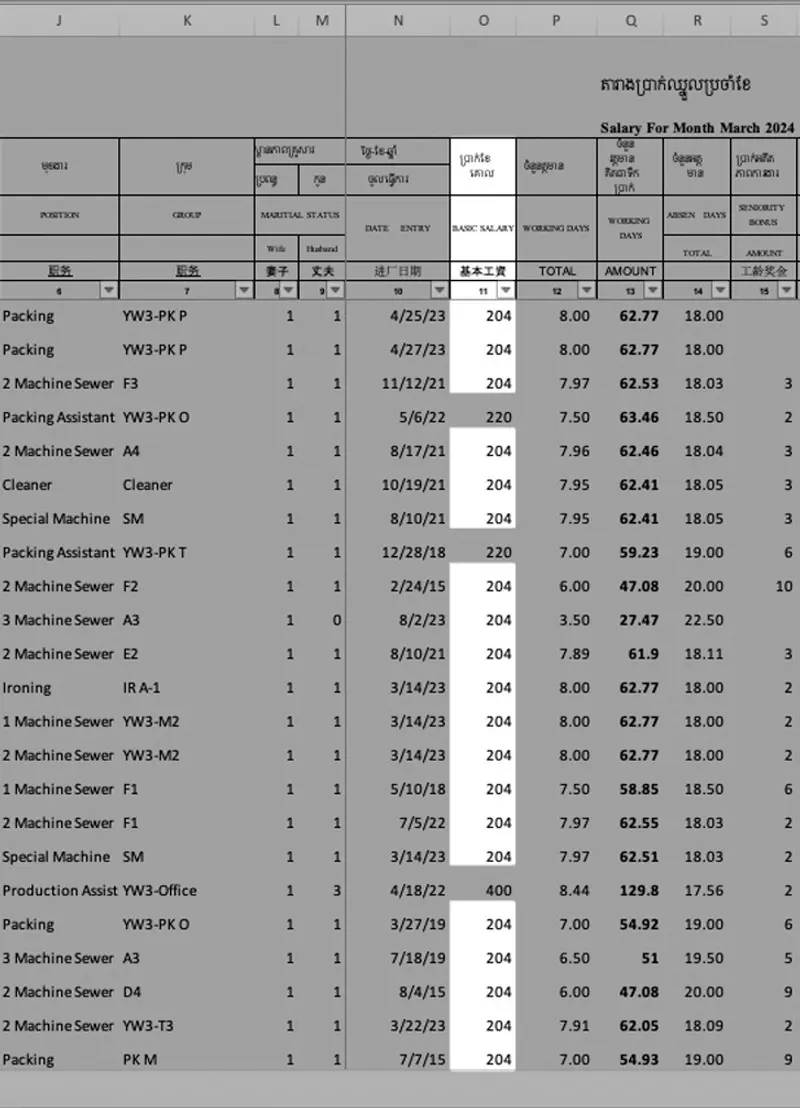

Davis obtained an Excel spreadsheet in English and Khmer, the language most generally spoken in Cambodia. It was a payroll ledger for Y&W Garment, which made child clothes for Nike from 2022 to 2023. Davis may see each worker’s job title, age, hiring date, gender and pay quantities.

This was one manufacturing facility in a provide chain made up of a whole lot, 3,720 employees out of greater than 1.1 million that Nike’s suppliers make use of globally. Nevertheless it was a uniquely complete window. Fast calculations confirmed that solely a tiny share of Y&W’s workforce — simply 1% — made 1.9 occasions the minimal wage, the quantity that Nike mentioned was typical.

Credit score:

Obtained by ProPublica. Highlights and redactions by ProPublica.

Davis linked with a bilingual freelance journalist in Phnom Penh, Keat Soriththeavy, who tracked down a few of the employees named within the payroll ledger. Now we had manufacturing facility sources on the bottom. We had somebody to assist Davis translate what they needed to say. And we had our spreadsheet. I advised Davis to e book a ticket for January.

On a Sunday morning, lower than a day after his airplane landed in Cambodia’s capital, Davis met a team of workers on their solely break day. After introductions by our employed translator, Davis pulled an iPad out of his journey bag and handed it round, asking whether or not the main points of the digital payroll ledger have been correct.

One after the other, every employee studied the entry by their title. “Appropriate?” Davis requested. Pause for translation.

“Sure.”

Across the desk they went: Appropriate. Sure. Appropriate.

Credit score:

Rob Davis/ProPublica

Davis spent the remainder of his 12-day go to touring by tuk-tuk — a tiny three-wheeled taxi named for its puttering engine — to satisfy employees in small villages round Phnom Penh. Cambodian garment employees are usually on the clock a minimum of six days every week, leaving restricted free time to spend with household or a visiting journalist. But with Keat’s assist, Davis managed to speak with a complete of 14, some prepared to be recognized by title. They advised him the cash they made in a 48-hour work week wasn’t sufficient to reside on and that they wanted time beyond regulation to make ends meet.

Credit score:

First picture: Keat Soriththeavy. Second picture: Rob Davis/ProPublica

When employees started telling Davis that folks fainted within the scorching manufacturing facility and wanted to be handled at its clinic, he messaged me to gauge my response. I requested: May he discover a health care provider who handled them? In a short time, Davis obtained a cellphone quantity for a clinic staffer prepared to speak. The medical employee helped us quantify the size of the issue, telling Davis as many as 15 folks a month turned too weak to work within the scorching months of Might and June. (As utilized in Cambodia, the time period “fainted” can describe changing into too weak to work.)

ProPublica photojournalist Sarahbeth Maney adopted on Davis’ path a month later. She documented, with intimate portraiture, the house life of individuals from a manufacturing facility the place base pay began at about $1 per hour.

Credit score:

Sarahbeth Maney/ProPublica

Nike didn’t reply detailed questions from Davis about wages or faintings, as a substitute issuing a written assertion. The corporate mentioned it’s “dedicated to moral and accountable manufacturing” and that it expects suppliers “to proceed making progress on honest compensation for an everyday work week.”

Representatives of Y&W Garment and its Hong Kong father or mother, Wing Luen Knitting Manufacturing facility Ltd., didn’t reply to Davis’ emails, textual content messages or cellphone calls. Haddad Manufacturers, which Y&W employees advised Davis served as an middleman for Nike on the Phnom Penh facility, didn’t reply to emails asking about situations there.

As Davis was drafting his story, President Donald Trump’s plan to boost tariffs on items manufactured abroad despatched Nike’s inventory costs tumbling. One declared purpose was to reverse the financial forces that drove Nike and others to make their merchandise in locations like Cambodia and never the U.S. It appeared, actually, like Nike’s observe document within the area is likely to be shedding relevance.

However specialists advised Davis and Kish, our reporting associate at The Oregonian, fairly the alternative. Moderately than convey jobs dwelling, manufacturers would possibly merely squeeze their overseas suppliers for larger productiveness.

It made the problems that drove Davis from the start as urgent as they’ve ever been. Had Nike lived as much as its guarantees in Southeast Asia?

At one Cambodian manufacturing facility, Davis’ tenacity introduced us a easy reply: No.

Credit score:

Sarahbeth Maney/ProPublica