August 6, 2025

PRESS RELEASE

Apple will increase U.S. dedication to $600 billion, declares American Manufacturing Program

Apple helps greater than 450,000 jobs with 1000’s of suppliers and companions throughout all 50 states — together with vital expansions in Arizona, California, Iowa, Kentucky, Nevada, New York, North Carolina, Oregon, Texas, and Utah

CUPERTINO, CALIFORNIA Apple at this time introduced a brand new $100 billion dedication to America, a big acceleration of its U.S. funding that now totals $600 billion over the following 4 years. At the moment’s announcement consists of the formidable new American Manufacturing Program (AMP), devoted to bringing much more of Apple’s provide chain and superior manufacturing to the U.S. By way of AMP, Apple will improve its funding throughout America and incentivize international firms to fabricate much more essential elements in america.

“At the moment, we’re proud to extend our investments throughout america to $600 billion over 4 years and launch our new American Manufacturing Program,” stated Tim Cook dinner, Apple’s CEO. “This consists of new and expanded work with 10 firms throughout America. They produce elements which are utilized in Apple merchandise bought everywhere in the world, and we’re grateful to the President for his assist.”

Apple components and elements manufactured within the U.S. ship to prospects around the globe; in actual fact, roughly two-thirds of the elements made within the U.S. are exported to prospects outdoors the U.S.

At the moment, Apple companions with 1000’s of suppliers throughout all 50 states, supporting greater than 450,000 provider and associate jobs. Within the subsequent 4 years, Apple plans to straight rent 20,000 individuals within the U.S. — the overwhelming majority centered on R&D, silicon engineering, software program growth, and AI and machine studying.

Apple American Manufacturing Program

Apple is working with its suppliers to speed up manufacturing within the U.S. by means of the brand new American Manufacturing Program. The primary AMP companions embody Corning, Coherent, GlobalWafers America (GWA), Utilized Supplies, Texas Devices (TI), Samsung, GlobalFoundries, Amkor, and Broadcom. This builds on Apple’s July dedication to purchase American-made uncommon earth magnets from MP Supplies.

The American Manufacturing Program will assist fund a main growth of Apple’s long-standing partnership with Corning, bringing the world’s largest and most superior smartphone glass manufacturing line to a manufacturing facility in Harrodsburg, Kentucky. The growth signifies that quickly, each iPhone and Apple Watch bought around the globe will probably be constructed with Kentucky-made cowl glass. The 2 firms may also open a brand new Apple-Corning Innovation Heart in Kentucky.

Apple has additionally entered into a brand new multiyear settlement with Coherent, a long-standing associate that produces the VCSEL lasers that allow a number of options — together with Face ID — on iPhone and iPad units shipped around the globe. This work takes place at Coherent’s Sherman, Texas, facility.

In July, Apple additionally dedicated to purchasing American-made uncommon earth magnets developed by MP Supplies — the one absolutely built-in uncommon earth producer in america — considerably increasing their flagship Independence facility in Fort Price, Texas. These magnets will turn into a part of Apple units shipped around the globe. The 2 firms may also set up a cutting-edge uncommon earth recycling line in Mountain Move, California.

Apple Expands Finish-to-Finish American Silicon Provide Chain

With these new partnerships, Apple is main the creation of an end-to-end silicon provide chain in america, with companions in each key side of silicon manufacturing.

This U.S. silicon provide chain is on observe to provide greater than 19 billion chips for Apple merchandise in 2025. That features TSMC in Arizona, which is producing tens of thousands and thousands of chips for Apple utilizing one of the vital superior course of applied sciences in America. Apple is that this manufacturing facility’s first and largest buyer.

“Apple engineers work intently with suppliers throughout america to create silicon chips which are on the forefront of innovation,” stated Sabih Khan, Apple’s chief working officer. “We’re dedicated to supporting U.S. suppliers concerned in each key stage of the chip-making course of — from the earliest levels of analysis and growth, to ultimate fabrication and packaging. We wish America to guide on this essential {industry}, and we’re increasing our efforts to develop a silicon manufacturing ecosystem that may profit innovators throughout America.”

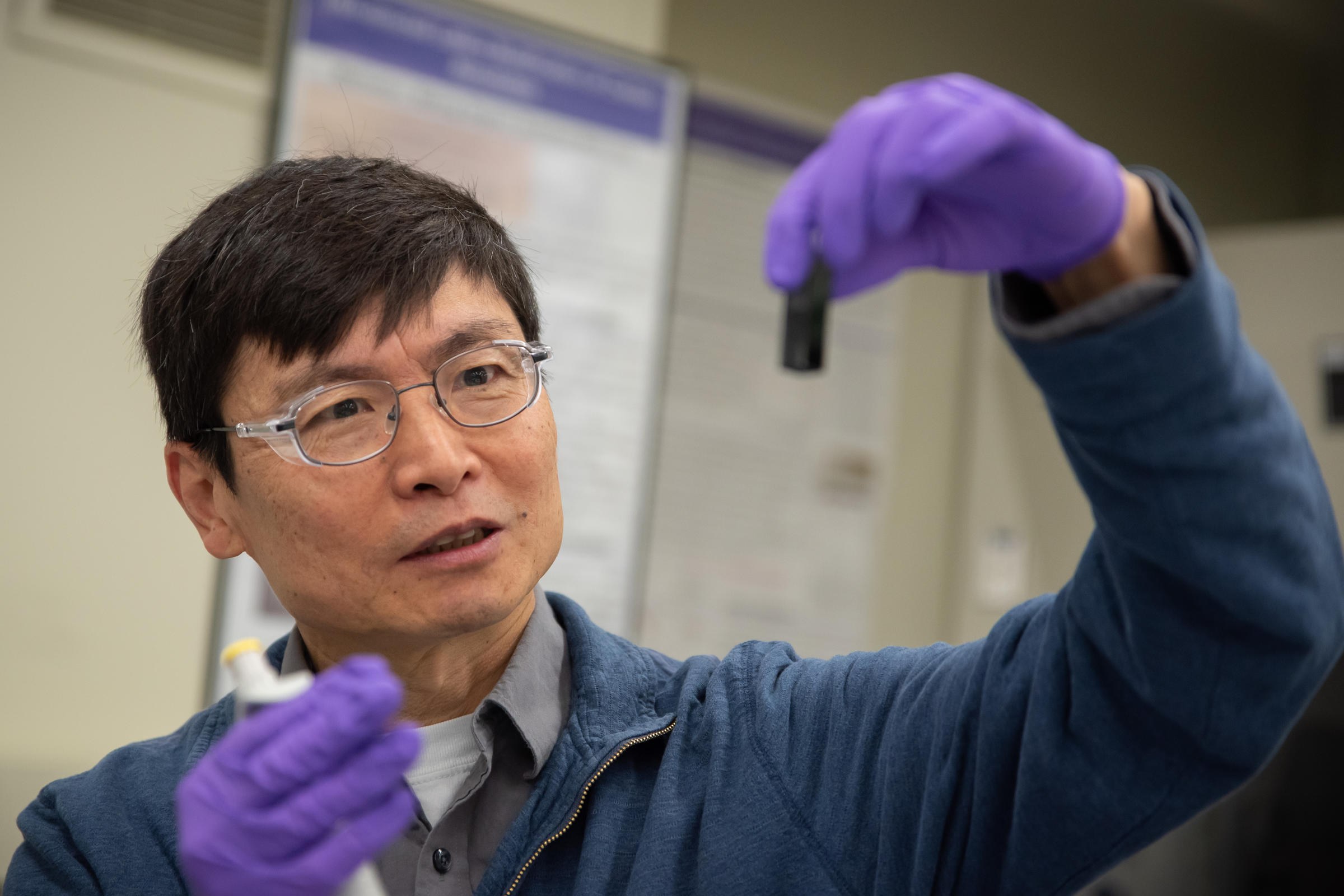

- Wafers are the constructing block of any silicon chip, and Apple is partnering with GlobalWafers America in Sherman, Texas, to provide superior wafers to be used in U.S.-based semiconductor fabs for the primary time. American chip fabs like TSMC in Phoenix, Arizona, and Texas Devices in Sherman, Texas, will use GWA’s 300mm wafers to provide chips for iPhone and iPad units bought within the U.S. and around the globe. GWA makes use of silicon from U.S. sources, together with from Corning’s Hemlock Semiconductor, to provide the world’s most superior silicon wafers.

- Apple can be partnering straight with Utilized Supplies to spice up the manufacturing of semiconductor manufacturing tools within the U.S. The Utilized website in Austin, Texas, is a pivotal hub for manufacturing cutting-edge chip tools.

- Fabs take naked wafers and switch them into chips. Apple and Texas Devices are increasing their partnership to extend future product collaboration and significant U.S. capability for this work. Apple is making a brand new dedication with TI, which can assist extra instrument installations at its facility in Lehi, Utah, and a brand new facility in Sherman, Texas. These services are residence to TI’s most superior course of applied sciences and use American-made chip manufacturing tools from Utilized Supplies’ manufacturing facility in Austin, in addition to superior silicon wafers from GlobalWafers America. These services will manufacture essential foundational semiconductors used for Apple merchandise, together with iPhone units shipped within the U.S. and around the globe.

- Apple can be working with Samsung at its fab in Austin, Texas, to launch an progressive new expertise for making chips, which has by no means been used earlier than anyplace on the planet. By bringing this expertise to the U.S. first, this facility will provide chips that optimize energy and efficiency of Apple merchandise, together with iPhone units shipped everywhere in the world.

- GlobalFoundries and Apple have additionally entered an settlement to carry extra semiconductor manufacturing to america, centered on manufacturing cutting-edge wi-fi applied sciences and superior energy administration — essential applied sciences that allow longer battery life and enhanced connectivity in Apple units. The partnership will carry new capabilities, jobs, and expertise to the GlobalFoundries semiconductor facility in Malta, New York.

- Packaging is the ultimate essential step in manufacturing silicon chips. Apple is investing in Amkor’s new superior chip packaging and check facility in Arizona, and will probably be its first and largest buyer. This can speed up the event of packaging capabilities in America, meaningfully strengthening the semiconductor provide chain within the U.S. This facility will bundle and check Apple silicon manufactured on the close by TSMC fab, and create chips utilized in iPhone units shipped around the globe.

Apple can be working with Broadcom and GlobalFoundries to develop and manufacture extra mobile semiconductor elements within the U.S. These elements are essential for 5G communications in Apple merchandise.

New and Expanded Amenities Throughout the U.S.

Earlier this 12 months, development started in Houston on the brand new manufacturing facility supporting manufacturing of superior Apple servers, and in July, the ability produced its first check unit. The 250,000-square-foot server manufacturing facility is slated to start mass manufacturing in 2026.

Beforehand manufactured outdoors the U.S., the servers from Houston will play a key function in powering Apple Intelligence, and are the muse of Non-public Cloud Compute, which mixes highly effective AI processing with essentially the most superior safety structure ever deployed at scale for AI cloud computing. The servers carry collectively years of R&D by Apple engineers, and ship the industry-leading safety and efficiency of Apple silicon to the information middle.

In Detroit, registration is now open for the brand new Apple Manufacturing Academy, which was introduced in February and is about to open on August 19. The academy will supply consultations and programs to small and medium-sized enterprise on how they’ll implement superior manufacturing and AI into their manufacturing applications.

Building can be underway in Maiden, North Carolina, the place Apple is increasing the capability of its knowledge middle with a big funding in its state-of-the-art facility that helps North American customers of Apple providers. The growth builds on greater than $5 billion that Apple has already invested in Catawba County.

Apple’s Maiden facility helps Apple’s providers corresponding to iCloud, the App Retailer, Apple Music, iMessage, Apple TV+, Apple Sports activities, and extra. The expanded capability may also assist assist the expansion of Apple Intelligence. As with all of Apple’s services, the information middle is powered by 100% renewable vitality sourced from Apple-created tasks within the area.

Apple can be increasing knowledge middle capability in states throughout the nation, with development underway in Iowa, Nevada, and Oregon.

In the meantime, development continues on Apple’s second campus in Austin. Apple has greater than 13,000 crew members throughout Texas, together with 1000’s already working from the three accomplished workplace buildings, which exceed 1 million sq. toes. The three buildings at present below development embody an expansive new R&D lab house for Apple’s {Hardware} Engineering, {Hardware} Know-how, and Software program Engineering groups.

This press launch comprises forward-looking statements, inside the which means of the Non-public Securities Litigation Reform Act of 1995. These forward-looking statements embody with out limitation these about Apple’s plans for future investments and growth. These statements contain dangers and uncertainties, and precise outcomes might differ materially from any future outcomes expressed or implied by the forward-looking statements. Extra info relating to potential dangers and different components that would have an effect on the corporate are included in Apple’s filings with the SEC, together with within the “Danger Components” and “Administration’s Dialogue and Evaluation of Monetary Situation and Outcomes of Operations” sections of Apple’s most not too long ago filed periodic stories on Type 10-Okay and Type 10-Q and subsequent filings. Apple assumes no obligation to replace any forward-looking statements or info, which converse solely as of the date they’re made.

About Apple

Apple revolutionized private expertise with the introduction of the Macintosh in 1984. At the moment, Apple leads the world in innovation with iPhone, iPad, Mac, AirPods, Apple Watch, and Apple Imaginative and prescient Professional. Apple’s six software program platforms — iOS, iPadOS, macOS, watchOS, visionOS, and tvOS — present seamless experiences throughout all Apple units and empower individuals with breakthrough providers together with the App Retailer, Apple Music, Apple Pay, iCloud, and Apple TV+. Apple’s greater than 150,000 staff are devoted to creating the perfect merchandise on earth and to leaving the world higher than we discovered it.

Press Contacts

Nick Leahy

Apple

Apple Media Helpline