Worldwide Enterprise Correspondent

BBC

BBCTake heed to Theo studying this text

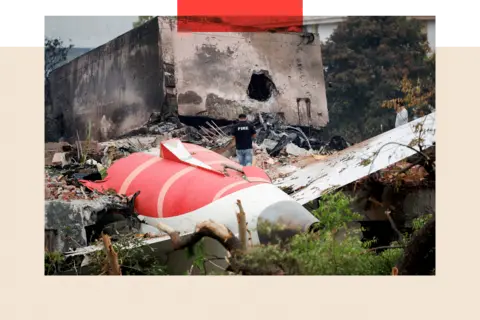

The Air India tragedy, through which not less than 270 individuals died, concerned one among Boeing’s most progressive and standard planes. Till now, it was thought of one among its most secure too.

We nonetheless have no idea why flight 171 crashed simply 30 seconds after take-off. Investigators have now recovered flight recorder knowledge and are working exhausting to seek out out. However the incident has drawn consideration to the plane concerned: the 787 Dreamliner, the primary of a contemporary era of radical, fuel-efficient planes.

Previous to the accident, the 787 had operated for almost a decade and a half with none main accidents and and not using a single fatality. Throughout that interval, in accordance with Boeing, it carried greater than a billion passengers. There are at the moment greater than 1,100 in service worldwide.

Nevertheless, it has additionally suffered from a sequence of high quality management issues.

Whistleblowers who labored on the plane have raised quite a few considerations about manufacturing requirements. Some have claimed that probably dangerously flawed plane have been allowed into service – allegations the corporate has constantly denied.

The Sonic Cruiser and the 9/11 impact

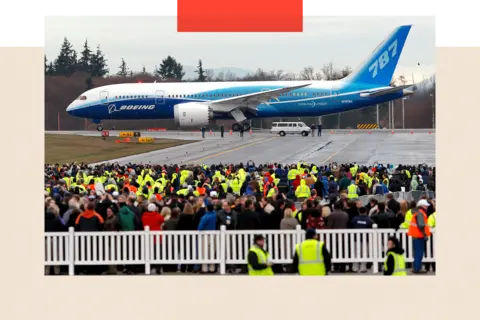

It was on a cold December morning in 2009 {that a} brand-new plane edged out onto the runway at Paine Area airport close to Seattle and, as a cheering crowd seemed on, accelerated right into a cloudy sky.

The flight was the fruits of years of growth and billions of {dollars} value of funding.

Getty Photos

Getty PhotosThe 787 was conceived within the early 2000s, at a time of rising oil costs, when the growing value of gasoline had grow to be a significant preoccupation for airways. Boeing determined to construct a long-haul airplane for them that may set new requirements in effectivity.

“Within the late Nineties, Boeing was engaged on a design referred to as the Sonic Cruiser,” explains aviation historian Shea Oakley.

This was firstly conceived as a airplane that may use superior supplies and the newest expertise to hold as much as 250 passengers at slightly below the pace of sound. The preliminary emphasis was on pace and chopping journey occasions, reasonably than gasoline financial system.

“However then the results of 9/11 hit the world airline business fairly exhausting,” says Mr Oakley.

“The airways advised Boeing what they actually wanted was probably the most fuel-efficient, economical long-range jetliner ever produced. They now needed an aeroplane with an identical capability to the Sonic Cruiser, minus the excessive pace.”

Boeing deserted its preliminary idea, and commenced work on what turned the 787. In doing so, it helped create a brand new enterprise mannequin for airways.

As a substitute of utilizing big planes to move big numbers of individuals between “hub” airports, earlier than inserting them on connecting flights to different locations, they may now fly smaller plane on much less crowded direct routes between smaller cities which might beforehand have been unviable.

Airbus’s superjumbo vs Boeing’s gasoline effectivity

On the time Boeing’s nice rival, the European big Airbus, was taking exactly the other method. It was growing the gargantuan A380 superjumbo – a machine tailored for carrying as many passengers as potential on busy routes between the world’s greatest and busiest airports.

In hindsight, Boeing’s method was wiser. The fuel-thirsty A380 went out of manufacturing in 2021, after solely 251 had been constructed.

“Airbus thought the longer term was big hubs the place individuals would at all times need to change planes in Frankfurt or Heathrow or Narita,” explains aviation analyst Richard Aboulafia, who’s a managing director at AeroDynamic Advisory.

“Boeing stated ‘no, individuals need to fly level to level’. And Boeing was extraordinarily proper.”

Getty Photos

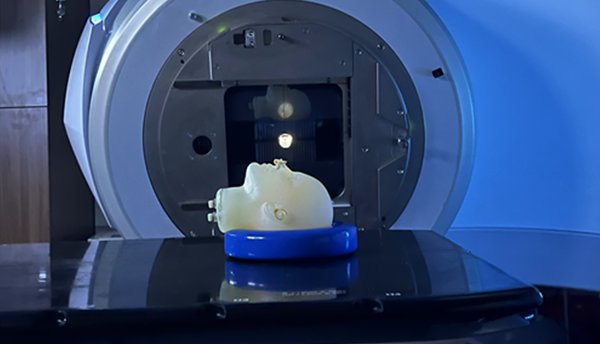

Getty PhotosThe 787 was a very radical plane. It was the primary industrial airplane to be constructed primarily of composites reminiscent of carbon fibre, reasonably than aluminium, in an effort to cut back weight. It had superior aerodynamics to cut back drag.

It additionally used extremely environment friendly trendy engines from Common Electrical and Rolls Royce, and it changed many mechanical and pneumatic techniques with lighter electrical ones.

All of this, Boeing stated, would make it 20% extra environment friendly than its predecessor, the Boeing 767. It was additionally considerably quieter, with a noise footprint (the world on the bottom affected by vital noise from the plane) that the producer stated was as much as 60% smaller.

Emergency landings and onboard fires

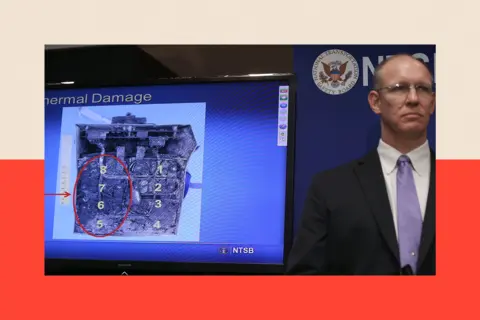

Not lengthy after the plane entered service, nevertheless, there have been critical issues. In January 2013, lithium-ion batteries caught fireplace aboard a 787 because it waited at a gate at Boston’s Logan Worldwide Airport.

Per week later, overheating batteries pressured one other 787 to make an emergency touchdown throughout an inner flight in Japan.

The design was grounded worldwide for a number of months, whereas Boeing got here up with an answer.

Getty Photos

Getty PhotosSince then, everyday operations have been smoother, however manufacturing has been deeply problematic. Analysts say this will, partially, have been on account of Boeing’s choice to arrange a brand new meeting line for the 787 in North Charleston, South Carolina – greater than 2000 miles from its Seattle heartlands.

This was carried out to make the most of the area’s low charges of union membership, in addition to beneficiant help from the state.

“There have been critical growth points,” says Mr Aboulafia. “Some notable manufacturing points, associated particularly to the choice to create Boeing’s first ever manufacturing line outdoors of the Puget Sound space.”

Damaging whistleblower allegations

In 2019, Boeing found the primary of a sequence of producing defects that affected the best way through which totally different components of the plane fitted collectively. As extra issues had been discovered, the corporate widened its investigations – and uncovered additional points.

Deliveries had been closely disrupted, and halted altogether between Could 2021 and July 2022, earlier than being paused once more the next yr.

Nevertheless, probably probably the most damaging allegations concerning the 787 programme have come from the corporate’s personal present and former workers.

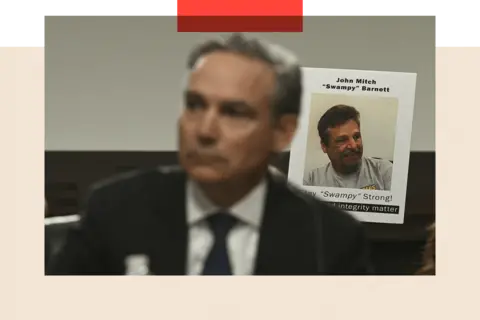

Among the many most outstanding was the late John Barnett, a former high quality management supervisor on the 787 manufacturing facility in South Carolina. He claimed that stress to supply planes as rapidly as potential had severely undermined security.

AFP by way of Getty Photos

AFP by way of Getty PhotosIn 2019, he advised the BBC that employees on the plant had did not observe strict procedures meant to trace parts by means of the manufacturing facility, probably permitting faulty components to go lacking. In some circumstances, he stated, employees had even intentionally fitted substandard components from scrap bins to plane in an effort to keep away from delays on the manufacturing line.

He additionally maintained that faulty fixings had been used to safe plane decks. Screwing them into place produced razor-sharp slivers of steel, which in some circumstances accrued beneath the deck in areas containing giant quantities of plane wiring.

His claims had beforehand been handed to the US regulator, the Federal Aviation Administration, which partially upheld them. After investigating, it concluded that not less than 53 “non-conforming” components had gone lacking within the manufacturing facility.

An audit by the FAA additionally confirmed that steel shavings had been current beneath the flooring of a lot of plane.

Boeing stated its board analysed the issue and determined it didn’t “current a security of flight challenge”, although the fixings had been subsequently redesigned. The corporate later stated it had “totally resolved the FAA’s findings relating to half traceability and carried out corrective actions to stop recurrence”.

‘A matter of time earlier than one thing massive occurs’

Mr Barnett remained involved that plane that had already gone into service could possibly be carrying hidden defects critical sufficient to trigger a significant accident. “I imagine it is only a matter of time earlier than one thing massive occurs with a 787,” he advised me in 2019. “I pray that I’m flawed.”

In early 2024, Mr Barnett took his personal life. On the time he had been giving proof in a long-running whistleblower lawsuit in opposition to the corporate – which he maintained had victimised him because of his allegations. Boeing denied this.

A lot of what he had alleged echoed earlier claims by one other former high quality supervisor on the plant, Cynthia Kitchens.

In 2011, she had complained to regulators about substandard components being intentionally faraway from quarantine bins and fitted to plane, in an try and hold the manufacturing line transferring.

Ms Kitchens, who left Boeing in 2016, additionally claimed workers had been advised to miss substandard work, and stated faulty wiring bundles, containing metallic shavings inside their coatings, had been intentionally put in on planes – making a danger of harmful short-circuits.

Boeing has not responded to those particular allegations however says Ms Kitchens resigned in 2016 “after being knowledgeable that she was being positioned on a efficiency enchancment plan”. It says that she subsequently filed a lawsuit in opposition to Boeing, “alleging claims of discrimination and retaliation unrelated to any high quality points”, which was dismissed.

Getty Photos

Getty PhotosExtra not too long ago, a 3rd whistleblower made headlines when testifying earlier than a senate committee final yr.

Sam Salehpour, a present Boeing worker, advised US lawmakers he had come ahead as a result of “the protection issues I’ve noticed at Boeing, if not addressed might lead to a catastrophic failure of a industrial aeroplane that may result in the lack of a whole lot of lives”.

The standard engineer stated that whereas engaged on the 787 in late 2020, he had seen the corporate introduce shortcuts in meeting processes, in an effort to pace up manufacturing and supply of the plane. These, he stated, “had allowed probably faulty components and faulty installations in 787 fleets”.

He additionally famous that on nearly all of plane he checked out, tiny gaps within the joints between sections of fuselage had not been correctly rectified. This, he stated, meant these joints can be liable to “untimely fatigue failure over time” and created “extraordinarily unsafe situations for the plane” with “probably catastrophic” penalties.

He advised that greater than 1,000 plane – the majority of the 787 fleet – could possibly be affected.

Boeing insists that “claims concerning the structural integrity of the 787 are inaccurate”. It says: “The problems raised have been topic to rigorous examination underneath US Federal Aviation Administration oversight. This evaluation has validated that the plane will keep its sturdiness and repair life over a number of many years, and these points don’t current any security considerations.”

‘Severe issues would have proven up’

There isn’t a query that Boeing has come underneath big stress lately over its company tradition and manufacturing requirements. Within the wake of two deadly accidents involving its bestselling 737 Max, and an extra critical incident final yr, it has been repeatedly accused of placing the pursuit of revenue over passenger security.

It’s a notion that chief government Kelly Ortberg, who joined the corporate final yr, has been working exhausting to overturn – overhauling its inner processes and dealing with regulators on a complete security and high quality management plan.

However has the 787 already been compromised by previous failures, which will have created ongoing security dangers?

Reuters

ReutersRichard Aboulafia believes not. “You already know. It has been 16 years of operations, 1,200 jets and over a billion passengers flown, however no crashes till now,” he says. “It is a stellar security file.”

He thinks that any main points would have already got grow to be obvious.

“I actually suppose manufacturing issues are extra of a short-term concern,” he says. “For the previous few years, there’s been far larger oversight of 787 manufacturing.

“For older planes, I feel any critical issues would have proven up by now.”

The Air India airplane that crashed in Ahmedabad was greater than 11 years previous, having first flown in 2013.

However the Basis for Aviation Security, a US organisation established by the previous Boeing whistleblower Ed Pierson that has beforehand been extremely important of the corporate, says it did have considerations about 787s previous to the current crash.

“Sure, it was a potential security danger,” claims Mr Pierson. “We monitor incident studies, we monitor regulatory paperwork. Airworthiness directives come out that describe varied points, and it does make you marvel.”

Getty Photos

Getty PhotosOne such challenge, he argues, is water probably leaking from washroom faucets into electrical gear bays. Final yr, the FAA instructed airways to hold out common inspections, following studies that leaks had been going undetected on sure 787 fashions.

Nevertheless, he stresses that the reason for the current tragedy remains to be unknown – and that it’s vital the investigation strikes ahead rapidly, in order that any issues, whether or not they lie with the plane, the airline or elsewhere, will be resolved.

For the second, nevertheless, the 787’s security file stays sturdy.

“We do not know at this level what precipitated the Air India crash,” says Scott Hamilton, managing director of aviation consulting agency Leeham Firm.

“However primarily based on what we do know concerning the airplane, I might not hesitate to get on board a 787.”

Prime picture credit score: Getty Photos

BBC InDepth is the house on the web site and app for the very best evaluation, with recent views that problem assumptions and deep reporting on the largest problems with the day. And we showcase thought-provoking content material from throughout BBC Sounds and iPlayer too. You possibly can ship us your suggestions on the InDepth part by clicking on the button beneath.